Necessary Upkeep: Tips for Extending the Lifespan of Komatsu Undercarriage Parts

Wiki Article

Effective Solutions: Undercarriage Components for Heavy Equipment

Quality undercarriage components play a significant function in making certain the smooth operation and durability of hefty machinery. In this discussion, we will certainly check out the relevance of spending in superior undercarriage components, common wear difficulties dealt with by hefty equipment operators, the benefits of timely substitutes, standards for picking trustworthy providers, and crucial maintenance pointers to extend the life expectancy of undercarriage parts.Relevance of Quality Undercarriage Components

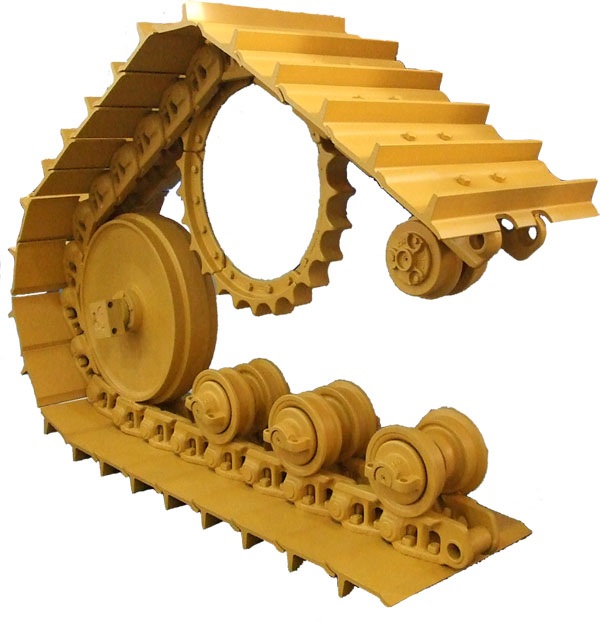

Quality undercarriage components are necessary components in making certain the toughness and performance of heavy equipment. The undercarriage of tools such as excavators, bulldozers, and track loaders plays an important role in supporting the device's weight, supplying security on different surfaces, and soaking up the influence of irregular surfaces. By investing in top notch undercarriage components, operators can substantially expand the life expectancy of their equipment and decrease the threat of unforeseen failures.One secret advantage of making use of top quality undercarriage parts is the enhancement of general equipment efficiency. Long lasting tracks, rollers, idlers, and sprockets decrease rubbing and ensure smoother activity, ultimately resulting in boosted productivity and effectiveness on task websites. Trusted undercarriage parts decrease downtime for upkeep and fixings, enabling operators to optimize their operational hours and task due dates.

Usual Undercarriage Use Issues

Advantages of Timely Replacement

One secret advantage of prompt undercarriage component substitute is boosted machine uptime. By changing used parts prior to they stop working, the danger of unanticipated break downs is decreased, decreasing downtime for repair work and maintenance. This aggressive strategy not only keeps the hefty equipment operational however also prevents potential damage to various other components that might arise from a stopping working undercarriage.

Moreover, changing undercarriage parts without delay can boost overall productivity. Spending in timely undercarriage part substitute is a proactive strategy that pays off in terms of boosted efficiency and reduced functional costs.

Selecting the Right Undercarriage Vendor

Selecting the appropriate undercarriage distributor is a crucial choice that considerably affects the performance and maintenance of hefty machinery. When choosing a provider for undercarriage parts, a number of aspects need to be considered to make certain optimal performance and cost-effectiveness. To start with, it is crucial to evaluate the provider's track record and experience in the market. A reputable supplier with years of experience is more most likely to give high-quality parts and trusted service. next page Additionally, consider the variety of products provided by the supplier. A vendor that provides a wide selection of undercarriage components for numerous heavy equipment brand names and designs can be helpful as it gives extra alternatives to satisfy particular needs.Balancing dependability, high quality, and cost-effectiveness is essential when choosing the best undercarriage provider for heavy machinery. By thoroughly examining these variables, you can pick a distributor that fulfills check that your needs and adds to the effective efficiency and maintenance of your hefty machinery.

Upkeep Tips for Extended Life Expectancy

To ensure an extensive life expectancy for hefty equipment undercarriage parts, applying an aggressive maintenance routine is crucial. Regularly evaluating undercarriage elements such as track chains, idlers, rollers, and gears for deterioration is essential. Any kind of indications of damage or extreme wear should be without delay dealt with to avoid more degeneration and potential failings. Additionally, maintaining the undercarriage clean from dust, debris, and harsh products can significantly lengthen its lifespan. Oiling moving components according to maker suggestions helps in reducing rubbing and prevent early wear. Keeping track of track stress and alignment is likewise vital to stop uneven endure the undercarriage parts. Purchasing high quality undercarriage components from credible providers is similarly important for making sure longevity. By complying with these upkeep suggestions faithfully, heavy machinery proprietors can optimize the performance and longevity of their undercarriage parts, eventually lowering downtime and operational prices.Verdict

In verdict, high quality undercarriage parts are essential for the reliable operation of hefty machinery. Picking a trusted vendor and complying with proper upkeep practices are key to making certain the prolonged life expectancy of undercarriage components.

Excessive wear and tear on undercarriage parts of hefty equipment can lead to considerable operational obstacles and boosted maintenance costs. Regular examinations, proper upkeep, and prompt substitutes of worn i loved this undercarriage parts are important to mitigate these usual wear troubles and make sure the ideal functioning of hefty equipment.

A provider that uses a broad choice of undercarriage parts for various hefty equipment brands and versions can be advantageous as it provides extra alternatives to fulfill details requirements.

By following these maintenance suggestions diligently, hefty equipment proprietors can enhance the efficiency and resilience of their undercarriage parts, ultimately lowering downtime and functional costs.

Report this wiki page